Environmental Consideration in Products

Improvement Objectives

The UACJ Group is working to enhance the functionality of aluminum materials to realize a low-carbon and recycling-oriented society.

We will contribute to solving global environmental issues by being at the center of a circular economy through efforts including by providing low-impact environmental products, such as our UACJ Smart brand of products, and by creating an optimal system for reusing aluminum scrap and other recyclable raw materials recovered from the market.

| Product Development and Improvement | Contributions that Benefit the Environment and Society |

|---|---|

| Development and application of aluminum can materials with outstanding recyclability | Promotion of resource recycling and greenhouse gas reduction |

| Development and application of high-performance heat exchanger tubes | Improving performance of heat exchangers to reduce equipment sizes and save resources |

| Development and improvement of aluminum materials for car air conditioners compatible with the European requirement to use CO2 as a refrigerant | Making lighter-weight vehicle bodies that save resources and improve fuel economy Fighting global warming by adopting CO2 as a refrigerant |

| Development and improvement of aluminum materials for HVs, EVs, PHVs, and FCVs | Making lighter-weight vehicle bodies that save resources and improve fuel economy |

UACJ products represent roughly half of all the materials used in aluminum cans manufactured in Japan, which in fiscal 2022 amounted to approximately 330,000 tons of material for 21.5 billion cans *. As part of our responsibility as the leading manufacturer of aluminum products, we actively promote the recycling of aluminum can scraps.

We are also simplifying and streamlining the delivery packaging of products and other items and streamlining our logistics processes for collecting and reusing packaging materials and racks.

*Source: Japan Aluminum Can Recycling Association estimate for fiscal 2022

Control of Chemical Substances included in Products

The UACJ Group strictly enforces proper controls over chemical substances used in its products. We respond to changes in environmental laws in Japan (such as to the Industrial Safety and Health Act and Chemical Substances Control Law) and overseas environmental laws (such as the EU REACH*1 regulation) by verifying the changes and making the necessary changes.

*1 REACH regulation: Registration, Evaluation, Authorization and Restriction of Chemicals.

Understanding and Communicating Information on Chemical Substances in Products

The UACJ management system ensures that we can fully communicate to our customers information from raw material manufacturers on the chemical substances contained in our products.

The Quality Assurance Department and the Environmental Management Department work together to provide chemical substance information in common industry formats in response to customer requests.

[Examples of Information Provision Formats]

- Safety Data Sheet (SDS) *2

- IMDS *3

- chemSHERPA *4

- *2 Safety Data Sheet (SDS): Documents with information on product hazards and other data and information in compliance with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS)

- *3 International Material Data System (IMDS): The material data system used in the automobile industry

- *4 Chemical information SHaring and Exchange under Reporting PArtnership (chemSHERPA): A system for communicating product chemical substance throughout the supply chain

Environmental Quality Management System Certifications by Customers

At its business locations required to have specified supplier certifications, the UACJ Group emphasizes the practice of chemical substance management that satisfies customer standards, and undergoes environmental quality management system certifications by customers. Going forward, we will continue to practice management that enables proper responses to customer demands.

Product Development that Helps to Lower Environmental Burden

Promoting the Use of Aluminum in Automobile Manufacturing

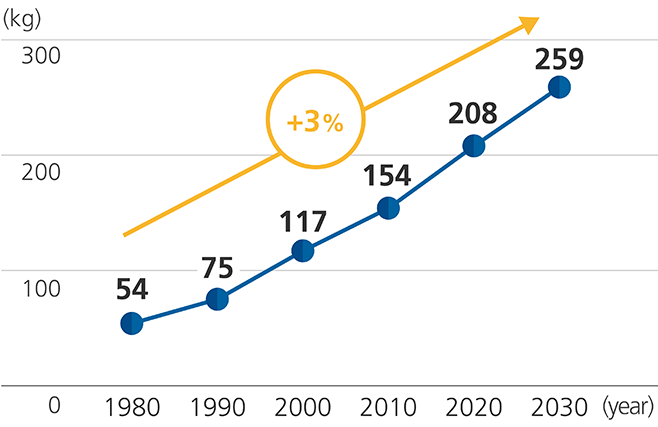

Aluminum is playing an important role in helping automakers improve engine performance and reduce vehicle weights to comply with stricter regulations.

Aluminum lightweight, strong, corrosion resistant, and easy to recycle but with a specific gravity of approximately one-third of iron. Automobiles currently use about 50% more aluminum than 15 years ago, and aluminum will likely be a key material used in EVs and other vehicles

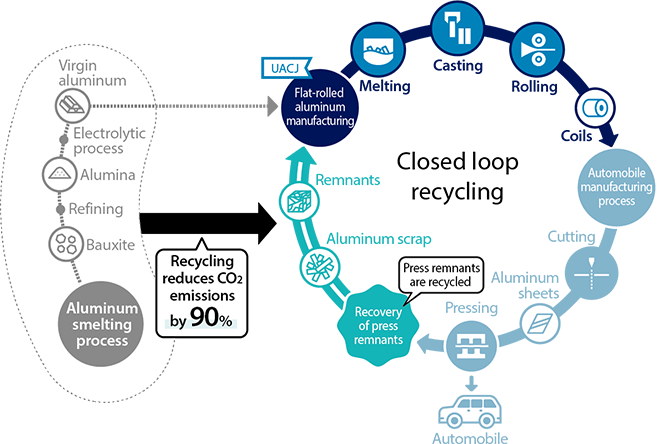

The UACJ Group is also contributing to closed-loop recycling of automobiles. Closed-loop recycling is collecting and recycling manufacturing scraps and post-consumer products and using the materials to create new products while maintaining product quality. Approximately 90% of the CO2 generated in the aluminum manufacturing process derives from the smelting process of new aluminum ingots. In addition, reusing press scraps in the new ingot smelting and refining process produces significantly less CO2 emissions. The UACJ Group’s closed-loop recycling system reduces the use of new aluminum ingots by collecting and reusing all the scrap created during vehicle manufacturing. This recycling process enables us to reduce the production of CO2.

Product Development that Helps to Reduce Atmospheric Carbon

Global warming is becoming increasingly evident in Japan with the increasing number of extremely hot days and natural disasters, and companies and organizations across the country are urgently implementing climate change countermeasures. Still, CO₂ emissions, a main cause of global warming, continue to increase and are said to be about 60% higher than 30 years ago. The Paris Agreement adopted at the 21st Conference of the Parties (COP21) to the United Nations Framework Convention on Climate Change held in Paris in December 2015, included decarbonization with the goal of reducing greenhouse gas emissions to virtually zero in the second half of the 21st century.

In October 2020, the Japanese government announced the 2050 Carbon Neutral Declaration, which aims to realize a decarbonized society by 2050 and reduce greenhouse gas emissions to net zero.

UACJ launched the new UACJ SMART brand of environmentally friendly products in 2021. In April 2023, we expanded the options for customers seeking improved environmental performance by offering UACJ SMART Mass Balance aluminum, which is produced using electricity generated from renewable energy sources and from scraps collected in a closed loop. The aluminum is also eligible for third-party compensation for greenhouse gas As we continue to offer more added value, we launched the new ALmitas+ brand in September 2023.

*UACJ SMART was renamed ALmitas+ SMART in November 2023.

Origin of ALmitas+ SMART

SMART is an acronym standing for “Sustainable Materials with Aluminum R (Recycle/Reduce/Replace) Technology” and expresses our intention to contribute to the realization of a sustainable society by making the most of aluminum’s strengths as a lightweight, recyclable material.

Manufacturing Foil for Lithium-ion Batteries for Automobiles

Zero greenhouse gas emissions means zero carbon and a complete halt to the use of oil, gas, and other fossil fuels. The automobile industry, therefore, is moving ahead with a shift to electric vehicles.

Lithium-ion batteries, which are essential for electric vehicles, use aluminum foil on the positive electrode and copper foil on the negative electrode. UACJ Foil Corporation, a member of the UACJ Group, is the only Japanese manufacturer capable of producing both aluminum and copper foil. Having excellent alloy and rolling technologies, UACJ Foil makes a unique contribution in improving the performance of lithium-ion batteries.

In China, public and private sectors are cooperating to promote the adoption of electric vehicles and this is expanding demand for lithium-ion batteries. Seizing on this opportunity, Ruyuan Dongyangguang UACJ Fine Aluminum Foil Co., Ltd., a company in which UACJ has invested, announced in 2018 that it will build a new battery foil production facility. The company aims to construct a production system integrating manufacturing of everything from foil base to collectors and foil for battery exteriors.